Ceramics

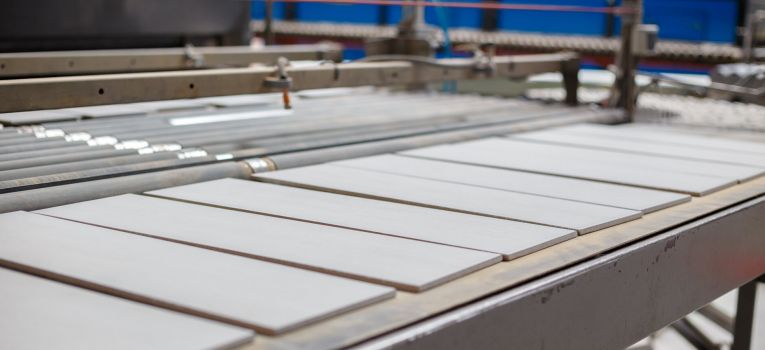

Over the years, our company has been providing refractory and thermal insulation materials and systems for thermal management of ceramic production.

We apply our experience to designing and installing reliable thermal solutions that aid in maintaining optimal firing conditions inside a furnace, enhancing productivity, energy efficiency, and extending furnace service life.

Our moulded dense refractory products are used for the construction of walls and arches of various thermal generating units for firing ceramic products.

We produce thermal insulation refractory bricks in standard and non-standard shapes. These products are widely used in roller-hearth, shuttle, tunnel, and hobby kilns due to their strength and outstanding insulation properties over the entire temperature range.

To increase the service life of kiln cars, we have developed an innovative lining scheme using dense and thermal insulation concretes.

For more demanding applications, our ceramic fibre mats, boards, and ready-to-install modules boast exceptional performance to weight ratio. Ceramic fibre products promote less heat absorption, lower fuel consumption, and more manageable maintenance.

For more information, contact us using the feedback form.